Cockpit Foundation

Another main aspect of the project that we have been working on for quite some time has also started to move forward. With work on the monocoque section estimated to wrap up in early 2024, I have needed to commit some serious time to making sure we can begin to advance on the next main section of the rebuild; the cockpit.

Along with my recent post about the main spar tubes being sent for heat treatment, one of the largest tasks to the start will be the machining of all 8 main wing spar fittings. These and the tubes form what Hawker called "panels", and are the foundation of the cockpit assembly and the aircraft itself!

The steel round sections in this image are the raw material that we are starting with, they are all 7.5" in diameter; there are two lengths, 14" and 18" weighing 175lbs and 225 lbs respectively. When the machining is done, they will be little more than 30lbs each!

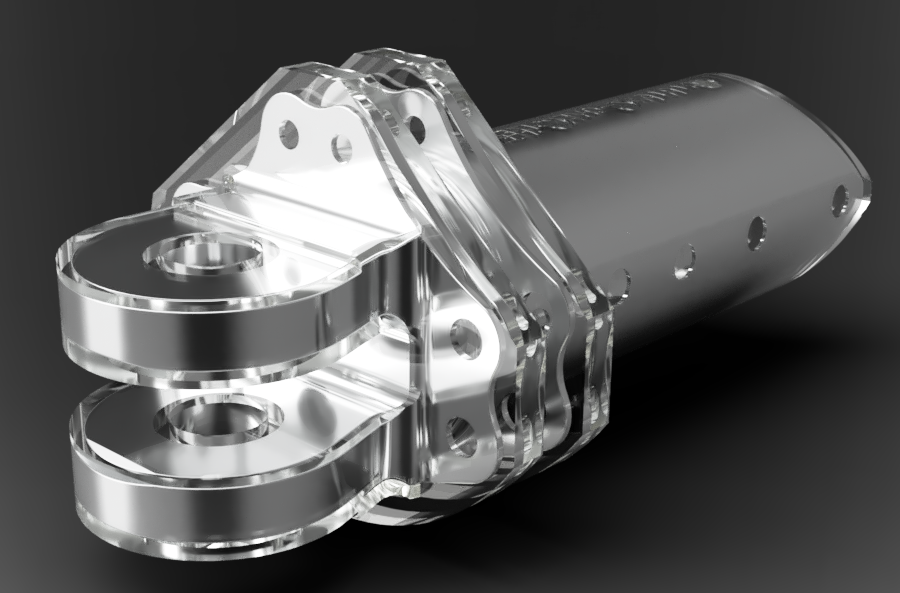

The process for these will take some time, and will begin with rough machining. The materials recently been sent to our 3rd party machine shop for this process. Here you can see some images of our CAD files testing the fit of each part inside of the raw material:

Once the oversized, roughed parts are machined, I will gather them up and bring them for heat treating to their final hardness. Then the parts will be tested for any cracking that could develop during heat treatment, and sent back to the machine shop for final machine work. Upon completion of this work, the parts will be sent for cadmium plating and returned to Typhoon Legacy.

This process is expected to be complete by end of spring 2024.