Skin Update

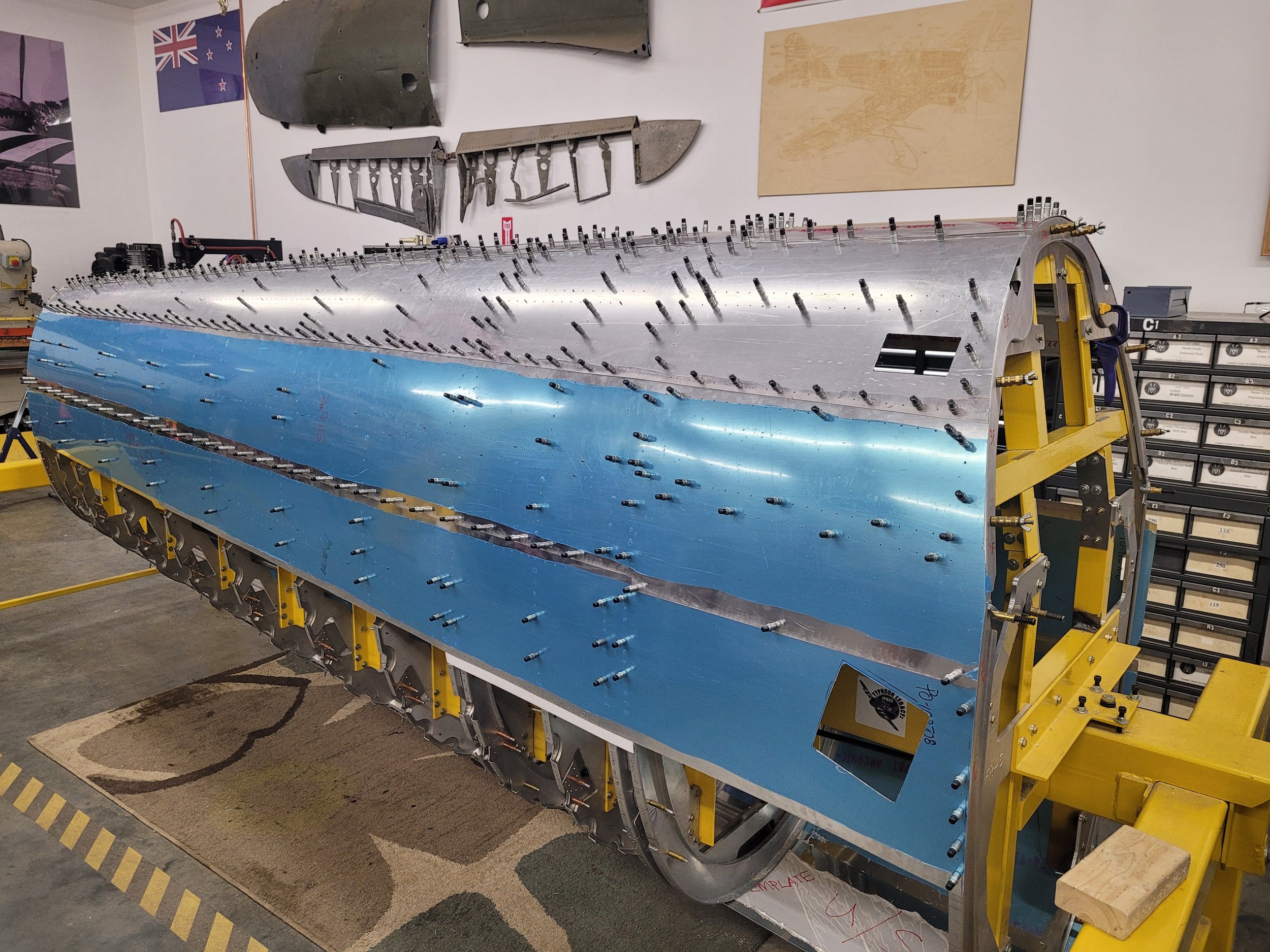

Work has been progressing very well on the the monocoque section over the past few weeks, all skins have now been fitted and I am now just tidying up a few missed holes and shrink touch-ups.

As you can see in the image above, the bottom edge of one skin still requires a touch more shrink (you can see a bulged section). While shrinking this section will only take a few minutes, it can be tedious removing all of the clecos and the panel to facilitate the work. The remaining holes that need to be drilled are ones which were skipped during the primary fitting, these are holes that may have had difficult access, or are waiting for additional structure to drill in conjunction with them. Often one or two holes here or there. In most cases I coordinate drilling these with skin removal as I work on other items.

I like to call this the clean-up phase of fitting. It is finicky work, but as you can see it really cleans up the assembly. These little jobs take quite a bit of time with the constant on and off of the skins; one panel at a time.

As I move along with the clean-up, I am also fitting the internal structure and brackets for the various forward end attachments and doors. In the forward two feet of monocoque, there are vents, the wireless door and rack supports, flare door, downward ident light, retractable footstep, footstep and hand hold! It’s a busy area that will be my primary focus over the next couple of weeks.

Overall it is quite satisfying to see this section coming together after sitting for nearly 3 years while we built up the Merlin. Getting close now… next up is the cockpit!!