The cockpit was stripped to its base structure

Noting critical fastener orientation before disassembly of components

Main spar fittings removed from spar tubes

Integrating structure attachment points

Dissecting the spar tubes to extract distance block information to aid with reverse engineering.

Aileron pulley brackets

Spar tube distance block

Cockpit material arrival, tubing and main spar fitting wrought blanks for machining.

A closer look at the rounds that will be machined into the main cockpit-spar fittings

Cockpit tubing cut to rough lengths for each strut

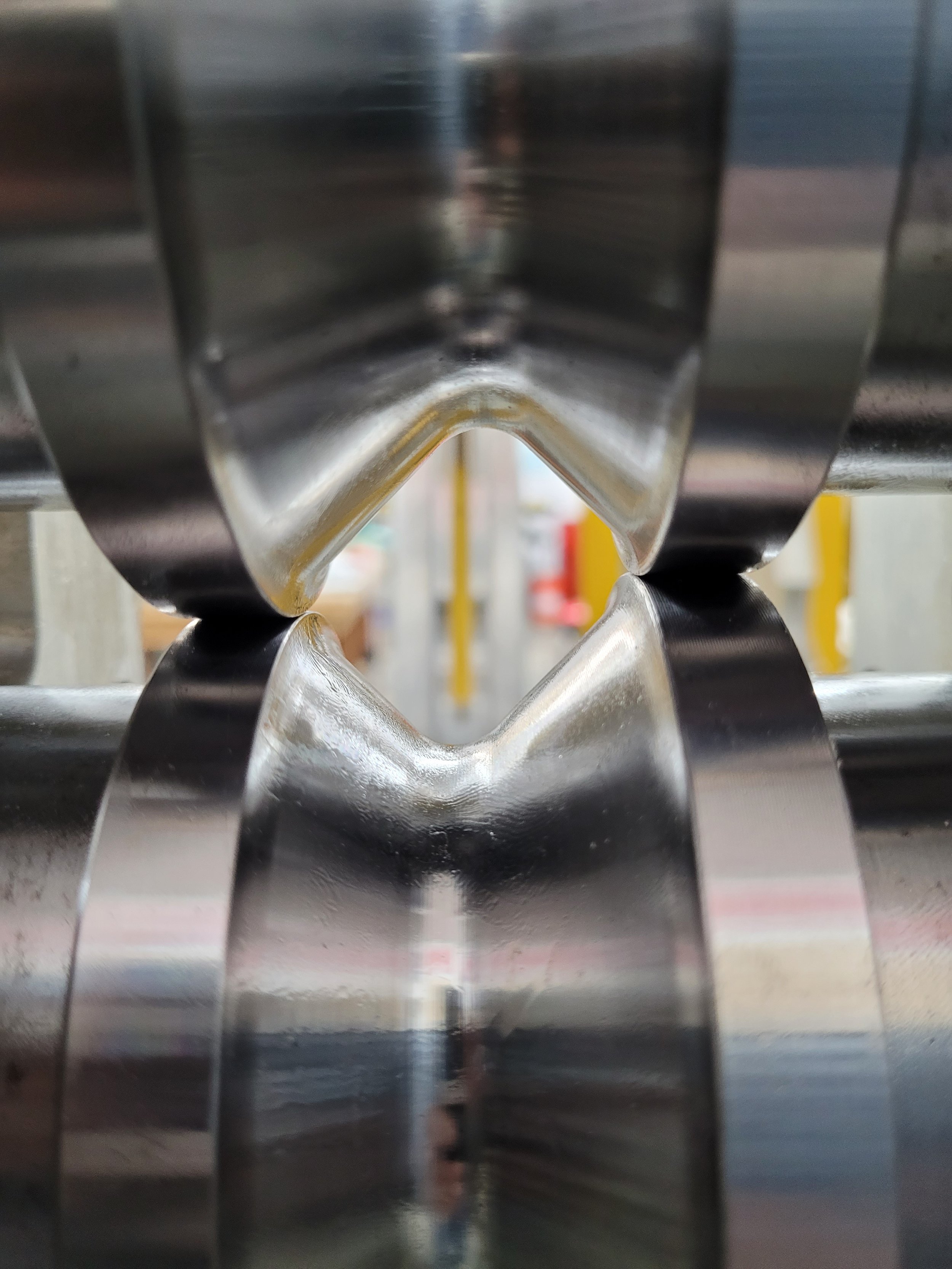

Typhoon Legacy's tube squaring machine view through the dies.

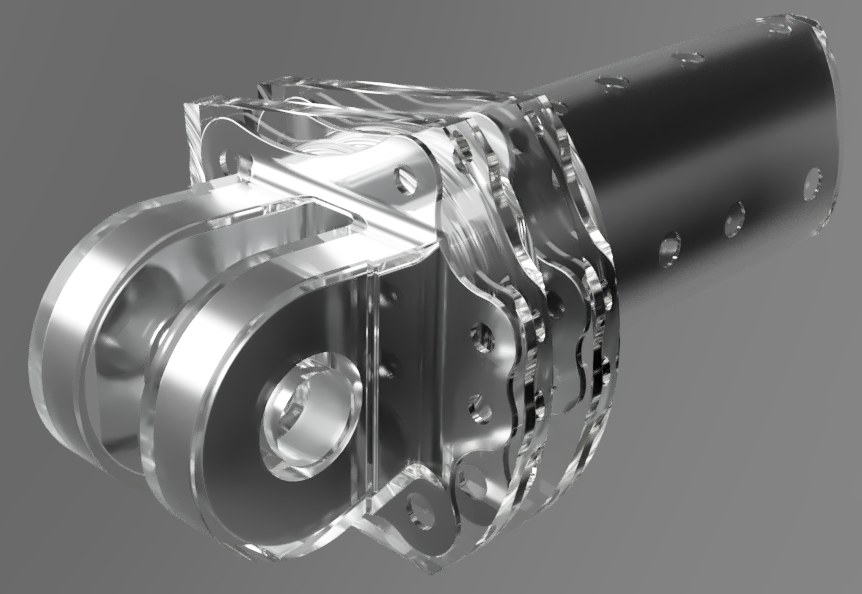

The tube squaring machine whilst fitting the reduction gear unit.

CAD models being used as tests for the added material requirements for rough cutting from our 7.5" round blanks.

The main spar tubes that run through the cockpit being prepared for heat treatment.