Fitting IN

With a massive thanks to those who have donated to our funding campaign, JP843’s wing spar fittings are really starting to take shape; 79 years after the last of these parts come off of the production line! Donations to help with completing these critical parts can be made securely though our website https://www.typhoonlegacy.com/donate

These are the four rear wing spar fittings rough machined. Once the forward components are complete, they will all be headed for heat treatment.

Coinciding with the advancement of the machine work, the amazing artwork produced by David Bathe is also soon to print. Printing will be done in Norway to aid with the signatures, and we will be getting these out to donors as soon as possible after they arrive in Canada.

These amazingly detailed prints are available in very limited quantities (only 50 will be produced), and are provided in exchange for significant donations to our funding campaign.

A little more about the spar fittings:

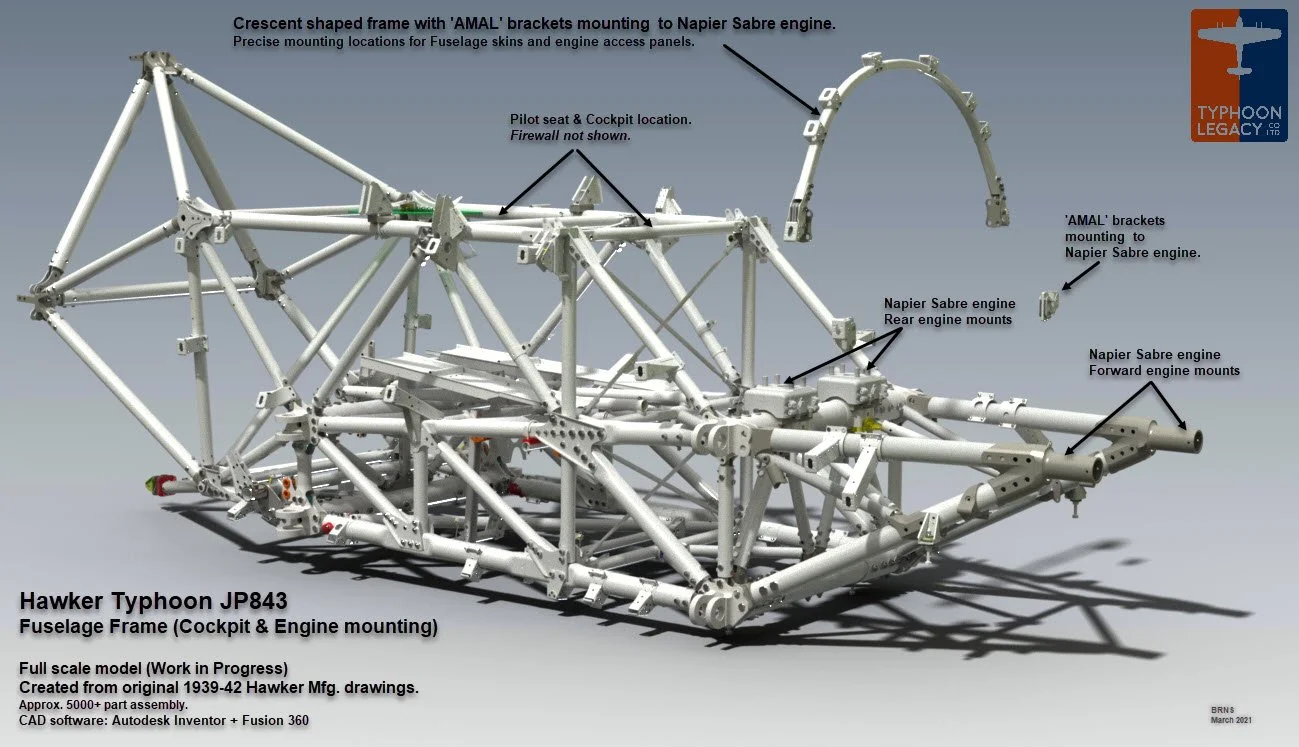

As many of you know, the Typhoon’s cockpit structure was made from mechanically joined tubular structure similar to that of the Hawker Hurricane and earlier designs. This structure was all built up around the most critical connections; the wing spar attachment points.

Here you can see the four front spar fittings attached to their tubular cross members.

In this assembly image, you can see how deeply these key parts get buried in the surrounding structure.

The wartime production fittings were made from a forged blank, using blanks significantly reduced the amount of material used and machine time required for production. It is likely these blanks ranged from 50-75lbs each. Due to the limited production quantities for the rebuild of JP843, forging these is not practical, so we are machining from bar stock. The blanks that we start with are 200-225lbs each!

7.5” diameter steel blanks for machining.

Due to all of that extra material, there is a lot of extra machine time required to get them to the approved rough dimensions. Thankfully, the use of modern multi axis CNC equipment helped with this.

Roughing in a 4 axis milling machine, this is the second stage which is done after the rough turning.

Seven of the eight fittings are shown here in various stages of completion. On the left of the image you can see the two upper forward spar fittings in the rough turned configuration. The boss on the inboard end is the rough area for the Sabre engine’s rear mounting.

Much more to come as this critical aspect of the project moves forwards!!